Top Reasons Why You Might Need to Relocate Machine Tools

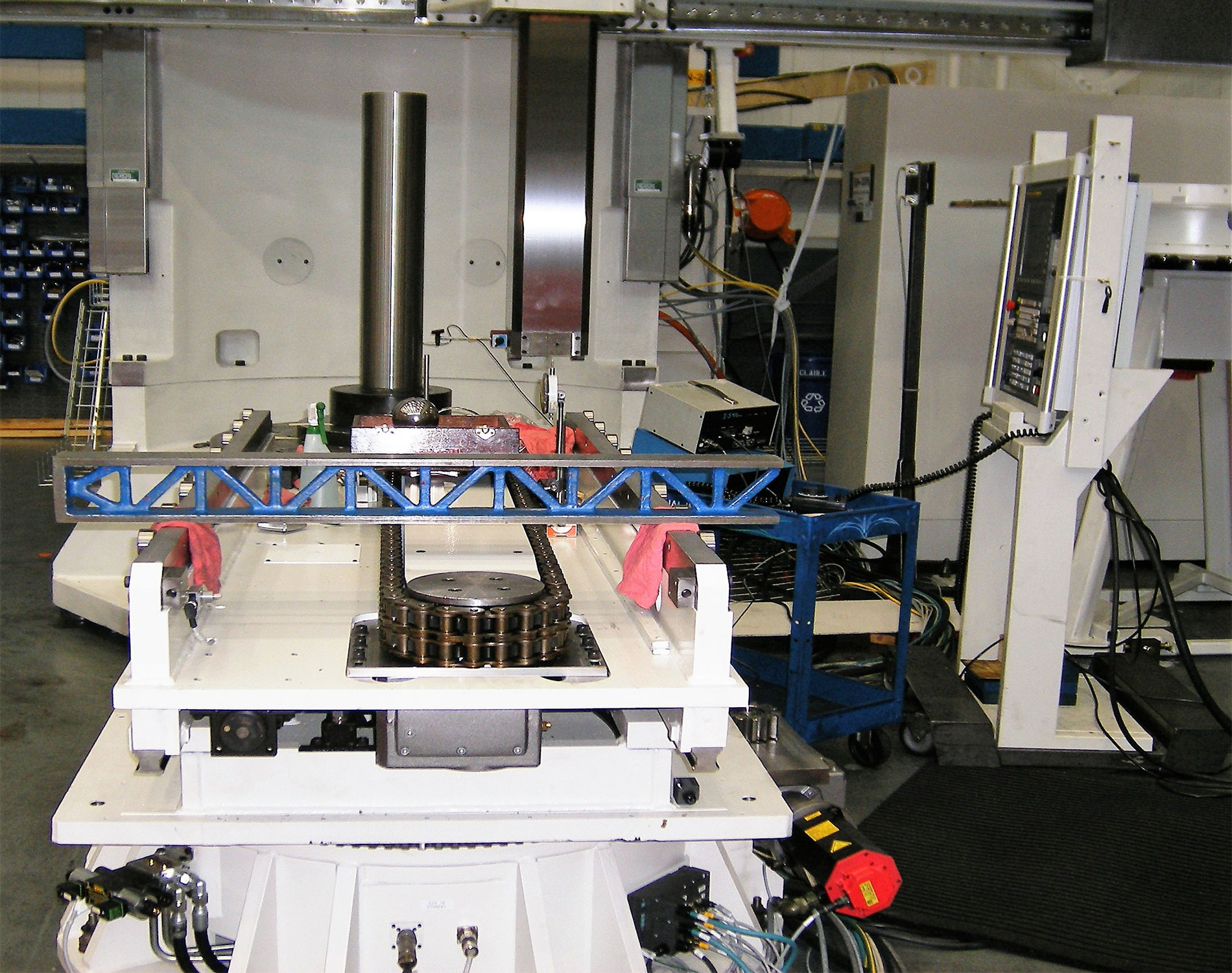

If you own an industrial plant in the energy, pharmaceutical, food & beverage, HVAC, packaging, or any other industry, there are chances that you have large pieces of machines that are critical to your business. But, sometimes, you may need to move large machines from one place to another. It means the machine needs to be disassembled in the current situation, moved, and then installed in the new location.

We are often asked what are the different situations when one needs to relocate their machine tools. So, here are some of the top situations that warrant relocation and machine tools installations in Texas –

In-House Shuffling

Often, companies organize their facilities by moving their machines within the same premises or outside of it. Sadly, heavy machines require special equipment and know-how as using a few employees for the job is not feasible or safe. Unless you have rigging equipment and experienced operators, you need a professional mover with machine tools installations in Texas and moving experience for the successful and safe move of your valuable machine.

When Moving Facilities

While many companies can easily manage by shuffling their machine tools within or outside their premises, sometimes, they need to be moved to another facility for structuring or growth. Just like any other machine relocation project, it requires an experienced moving crew to get the job done efficiently and safely. An experienced team will be able to dismantle the machinery, transport it to the new facility, and install it again properly.

Upgrading the Equipment

Another reason a business may need to move machines is when they are swapping or upgrading their existing machine tools. With the advancement in technology, businesses need to upgrade to new models every now and then to keep up with the changing needs of their customers. Skilled movers, along with all the required equipment, will exchange and swap the old machine with the new one.

Removing Machine from Facility

Apart from upgrading, plants may want to get rid of certain equipment that they no longer use. They may even sell their old equipment to a buyer and have to move it to their buyer’s location. Sometimes, the business may be closing down and need to clear out the facility. It is best to use professionals to get the machine uninstalled and off your property quickly.

Machine Repairs and Return

Machine tools experience wear and tear with constant use. General maintenance and repairs are often needed outside of their plant. Thus, they need to be transported to a repair facility where the experts can work on them. Once they are returned, the business will require machine tools installation in Texas. You may also need to return the machine to the manufacturer after the end of your leasing contract. A number of industrial plants lease their machine tools instead of buying one.

Relocation and installation of machine tools have become increasingly common. However, many industrial plant owners learn the wrong way that they need professional service and do not go the DIY route. Fortunately, you can find a number of moving companies in Houston offering complete machine tools services no matter what your needs are.

Apart from machinery relocation and rigging, Stone Machinery Movers offers installations, removal, disconnecting, and reconnecting of wiring and controls, alignment, and precision laser leveling services for machines tools of all sizes and shapes. To know more about our services or to speak to one of our experts, give us a call today!